Do you need to form or turn objects that are made from materials such as wood, plastic, or other substances? Are you looking for a method that is both quick and accurate to accomplish this? If this is the case, you might be curious about whether or not a drill press can be converted into a lathe.

This is no longer the distant dream of amateur handymen – it’s now possible with advances in tools and technology!

In this blog post, we’ll explore how a drill press can indeed be used as a substitute for a traditional lathe. We’ll cover all aspects of using your existing equipment, including safety precautions, material selection, and operational tricks that will ensure excellent results. Ready to get started? Read on!

Can a Drill Press Be Used As a Lathe?

The answer is yes, a drill press can be used as a lathe in certain circumstances. However, it is not recommended due to the risks associated with using a drill press as a lathe.

Drill presses are designed for drilling holes and tapping threads, while lathes are designed for cutting metal and other materials into intricate shapes and designs.

Using a drill press as a lathe is possible, but it can be dangerous and potentially disastrous due to the high speeds at which drill presses rotate. The tool spindle RPM of a drill press is typically much higher than that of a lathe,

meaning the material could spin out of control and become dangerously misaligned or even ejected from the drill press. This could cause serious injury or damage to property and should be avoided at all costs.

Additionally, using a drill press as a lathe may not produce the desired results that one would get from a dedicated lathe. Accuracy of cuts and other details are much more difficult to achieve on a drill press than on a specialized lathe.

This is due to the limited range and lack of precision controls that are available on a drill press, when compared to what one would find on a proper lathe.

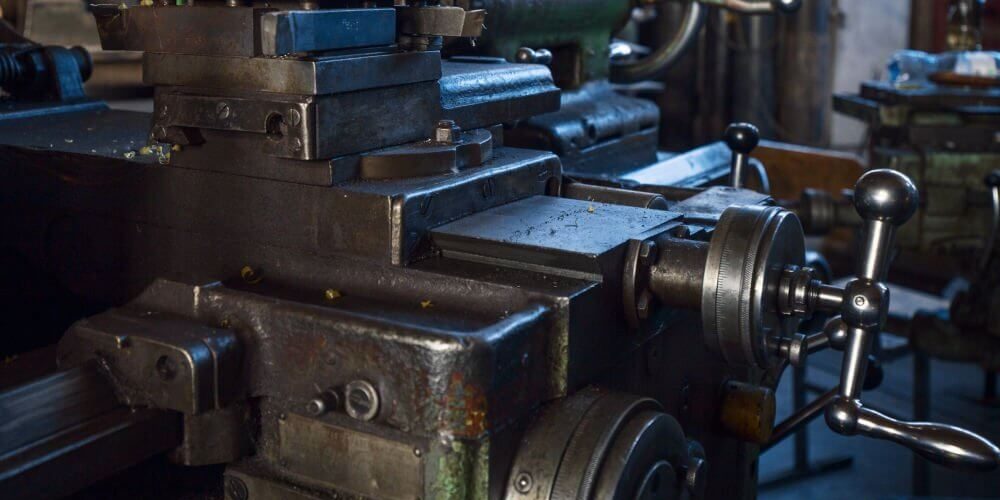

What is a Lathe?

A lathe is a machine used to shape and form various types of materials including wood, metal and plastic. It works by rotating the material while using tools such as cutters, drills or sanders to remove and shape the material into desired shapes. Lathes can also be used in machining operations such as drilling, tapping or boring.

Lathes are used in a variety of industries including automotive, aerospace and even plastics manufacturing. They’re also commonly used by hobbyists and DIY enthusiasts for projects such as wood carving or metalworking. With the right tools and skills, a lathe can be used to craft everything from furniture to sculptures.

Related: Do I Need a Drill Press?

Turn Your Drill Press Into a Vertical Woodworking Lathe? Step By Step Guideline

Converting a drill press into a vertical woodworking lathe can be a useful and cost-effective solution for certain woodworking projects. While it is important to note that a drill press is not designed to function as a lathe, with some modifications and safety precautions,

you can achieve basic turning operations. Here is a step-by-step guideline to help you with the process:

Step 1: Safety Precautions

Before starting any modifications, ensure you have appropriate safety equipment, including safety goggles, a dust mask, and ear protection. Make sure the drill press is unplugged and in the off position.

Step 2: Secure The Workpiece

Mount a faceplate or a chuck onto the drill press spindle. Use appropriate hardware to secure it tightly, ensuring it is centered and aligned with the drill press.

Step 3: Create a Tool Rest

To support your turning tools, you will need to create a tool rest. This can be accomplished by attaching a sturdy piece of wood or metal to the drill press table. Position the tool rest close to the workpiece, providing adequate support for your turning tools.

Step 4: Adjust the Height

Adjust the height of the drill press table so that the workpiece is at a comfortable working level. This will allow you to maneuver your turning tools effectively.

Step 5: Start Slowly

Begin by setting the drill press to its lowest speed setting. This will help you have better control over the turning process. Gradually increase the speed as needed, depending on the type of wood and the desired results.

Step 6: Turn the Workpiece

With the drill press turned on and the workpiece securely fastened, use your turning tools to shape and create desired woodturning profiles. Take small and controlled cuts, being mindful of the limitations of the drill press setup.

Step 7: Regularly Inspect and Adjust

Periodically inspect your setup to ensure everything remains secure. Check the tightness of the faceplate or chuck, as well as the stability of the tool rest. Make any necessary adjustments as you work to maintain safety and accuracy.

Step 8: Practice and Learn

Converting a drill press into a vertical woodworking lathe requires practice and experimentation. Take your time to become familiar with the process and gain a better understanding of its capabilities and limitations.

Remember, this setup is not a substitute for a dedicated wood lathe, which is specifically designed for woodturning operations. Exercise caution, prioritize safety, and consider investing in a lathe if you plan to pursue woodturning on a regular basis.

Related: How To Mount A Drill Press To Bench?

What Does a Lathe Machine Can Do?

A lathe machine is a versatile tool that can be used to create precision parts from a range of materials, including plastic, metal and wood. It has the ability to shape and cut components into intricate shapes by spinning them on its axis at high speeds.

A lathe machine is a versatile tool commonly used in machining and woodworking. It can perform various operations and tasks, including:

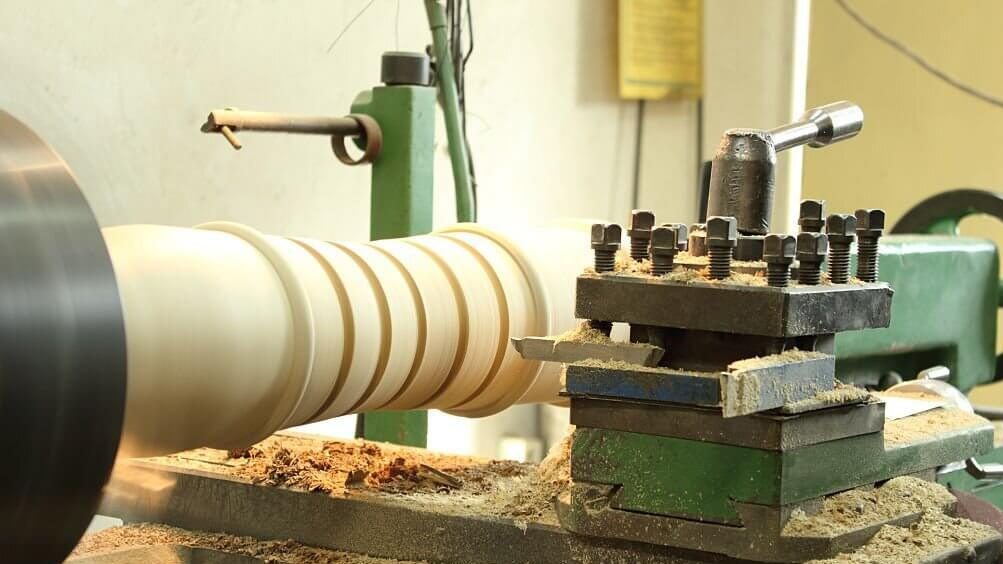

1. Turning:

The primary function of a lathe machine is to perform turning operations. It can rotate a workpiece on its axis and shape it symmetrically by removing material with cutting tools. This allows for the creation of cylindrical or conical shapes, such as spindles, shafts, and bowls.

2. Facing:

With a lathe machine, you can create flat surfaces on the ends of a workpiece, known as facing. This is useful for achieving precise alignment, creating smooth mating surfaces, or removing imperfections.

3. Drilling:

Many lathe machines have a spindle that can hold drill bits, enabling them to perform drilling operations. This is particularly useful for creating holes in a workpiece with accuracy and precision.

4. Boring:

A lathe machine can be used for boring operations, which involve enlarging or refining existing holes in a workpiece. By using specialized cutting tools, you can achieve precise diameter adjustments and create smooth, concentric holes.

5. Thread Cutting:

Lathe machines can also cut threads on a workpiece, allowing you to create internal or external threads of various sizes and pitches. This is commonly used in applications such as creating threaded fasteners or fitting components together.

6. Knurling:

Knurling is a process used to create a patterned texture on the surface of a workpiece, providing improved grip or aesthetic appeal. A lathe machine can perform knurling operations by pressing knurling wheels against the rotating workpiece.

7. Tapering:

With a lathe machine, you can create tapered shapes on a workpiece by gradually reducing its diameter along its length. This is useful for applications like creating tapered shafts or matching parts that need to fit together.

8. Parting:

Parting is the process of cutting off a section of the workpiece to create separate parts. A lathe machine equipped with a parting tool can cleanly separate the workpiece, allowing for the creation of individual components.

These are just a few examples of what a lathe machine can do. Its versatility and ability to shape and manipulate various materials make it a valuable tool in industries such as manufacturing, woodworking, metalworking, and engineering.

Drill Press Be Used As a Lathe FAQs

Q: Can I Use a Drill Press as a Lathe?

A: While a drill press is not designed to function as a lathe, with some modifications and safety precautions, you can perform basic woodturning operations using a drill press.

However, it is important to note that a drill press lacks many essential features and stability found in a dedicated lathe, so the results may not be as precise or efficient.

Q: What Modifications are Needed to Use a Drill Press as a Lathe?

A: Converting a drill press into a lathe requires attaching a faceplate or chuck to the drill press spindle to hold the workpiece securely.

You will also need to create a tool rest and adjust the drill press table height to accommodate the turning operation. These modifications allow you to perform basic woodturning tasks.

Q: Are There Limitations to Using a Drill Press as a Lathe?

A: Yes, there are limitations when using a drill press as a lathe. The drill press is not designed for lateral forces that are involved in woodturning, so it may lack the necessary stability for larger or more intricate projects.

Additionally, the speed range and control may be limited compared to a lathe, which can affect the quality of the turning results.

Conclusion

It is obvious that a drill press can be used as a lathe. Most of the same tasks as with a dedicated lathe can be accomplished with the right attachments and adjustments. Safety must always be upheld when using any type of power equipment.

It is important to take extra care when adjusting speeds and using cutting tools on the drill press. Additionally, research materials and techniques available for the specific model in order to get the most out of any project.

Investing adequate time into understanding what kind of work can be done will yield desired results in both efficiency and safety with any machine shop task.

Ultimately, turning the necessary components for projects that require precision accuracy are very rewarding endeavors whether it is done on a dedicated lathe or with a drill press which has been converted into one.